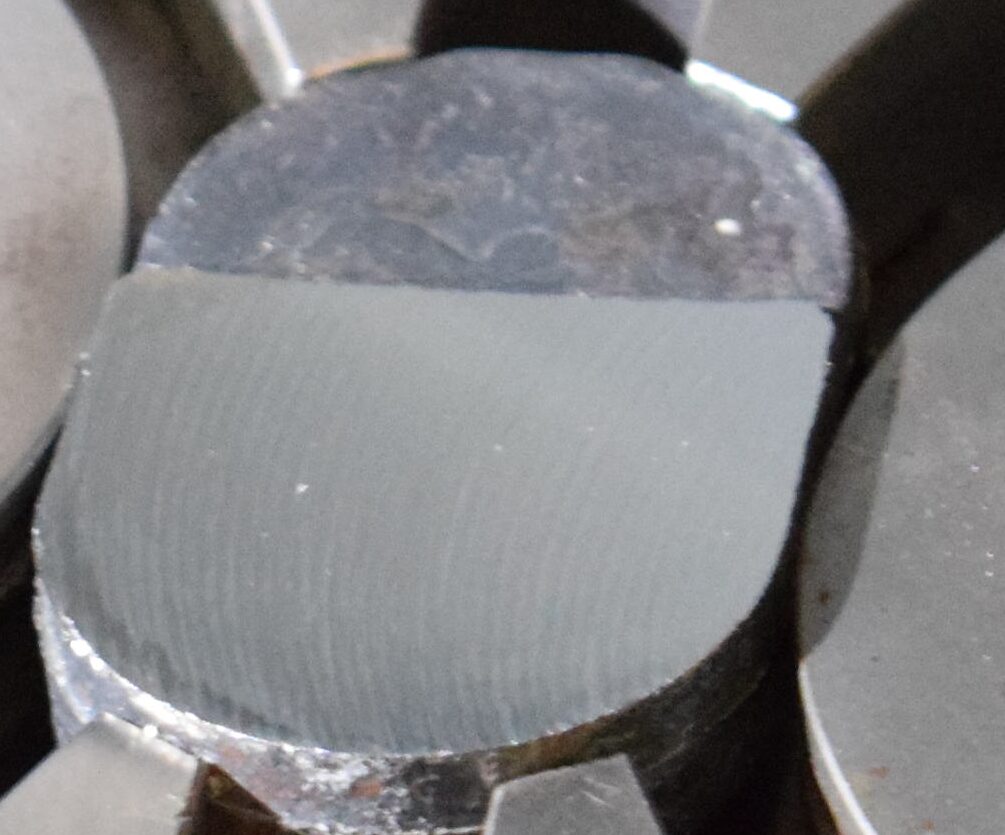

This example shows the significance of removing part from steel sample surface and is also the case with aluminum and pig iron in a different way of chemical composition of the sample itself. Typically the milling process is applied here.

Before pressing, it’s essential to finely grind the material to ensure proper homogeneity. QCS provides a range of disk vibration mills with various configurations. Even extremely hard materials like silicon carbide can be ground to a fine grain size, ensuring high-quality analysis. The achievable fineness depends on factors such as the material itself, input quantity, grinding aids utilized, and initial grain size. Throughout the grinding process, abrasion naturally occurs on the grinding stones and within the grinding box. It’s crucial that the grinding tools are appropriately hard and composed of materials that don’t introduce elements of analytical interest. To address this, various grinding boxes are offered to prevent the ingress of elements relevant to the analysis. We provide assistance in determining the optimal grinding parameters for your powder materials.

We offer manual, semi-automatic or fully automatic solutions for all process steps in sample preparation. However, if you aim to enhance efficiency without escalating expenses due to manual mistakes or longer operating time, our automation solutions is the answer. Here’s how automation can be beneficial:

Increase efficiency with sample analysis expenses by using your team for higher-value tasks. Our automation solutions are userfriendly products equipped with extensive functionality and operational adaptability. You can customize parameters of our systems effortlessly before, during, and after installation to address evolving needs

If you would like to discuss a specific topic, just request a meeting and we would love to talk about it.