SAMPLI PELLETPRESS40-R: SEMI-AUTOMATED PRESS FOR CEMENT SAMPLES

Intended use The automatic tablet press is intended for the

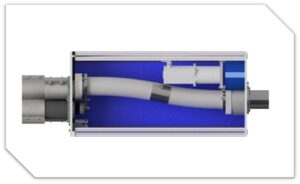

The station is used to send pneumatic tube containers to a higher-level system.

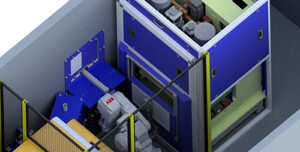

Input terminal indicates readiness for the input of a transport box.

The door is unlocked.

A can is inserted and set in the correct direction.

(Check by optical and inductive sensors) + optional RFID reader/writer checks the can recognition.

If all checks on the input were successful, the door can be closed. After the start command on the display, the door is locked electrically.

The lifting cylinder lifts the can into the transport tube and seals it.

Electrically operated valve releases the transport air.

Pneumatically controlled flap switches transmit or receive the position.

The station can remain in this position until the can is sent back from the laboratory or, after arrival, goes back into transmit and receive standby depending on the control in the main PLC.

You are welcome to leave your details and we will get in touch with you.

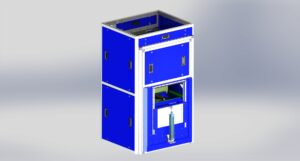

Intended use The automatic tablet press is intended for the

Intended use: The automatic mill is designed for fine grinding

You are welcome to leave your details and we will

You are welcome to leave your details and we will

You are welcome to leave your details and we will

You are welcome to leave your details and we will

You are welcome to leave your details and we will

If you would like to discuss a specific topic, just request a meeting and we would love to talk about it.