HARDWARE:

SOFTWARE:

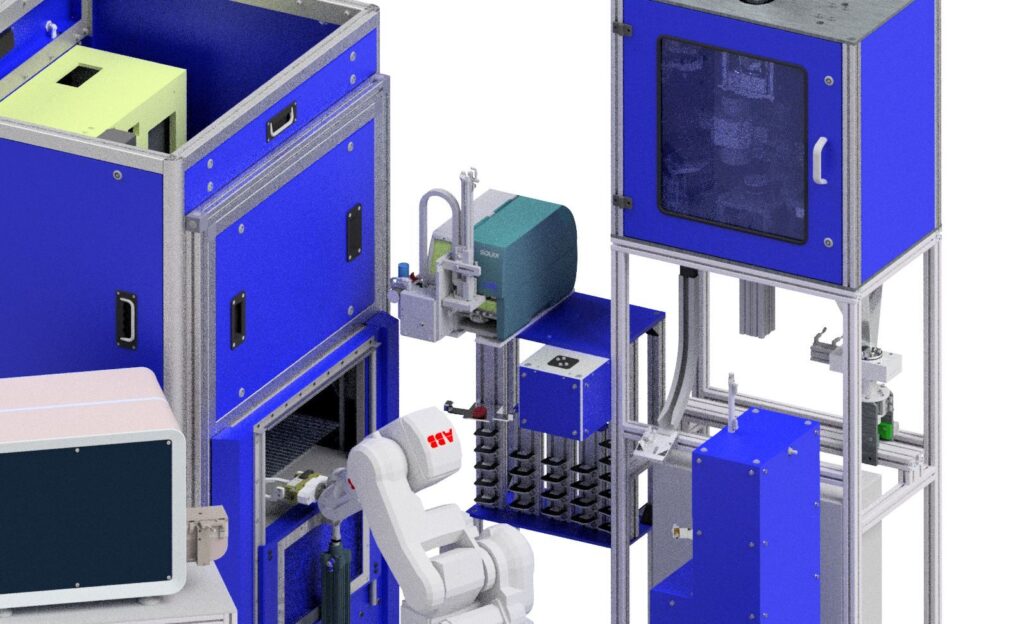

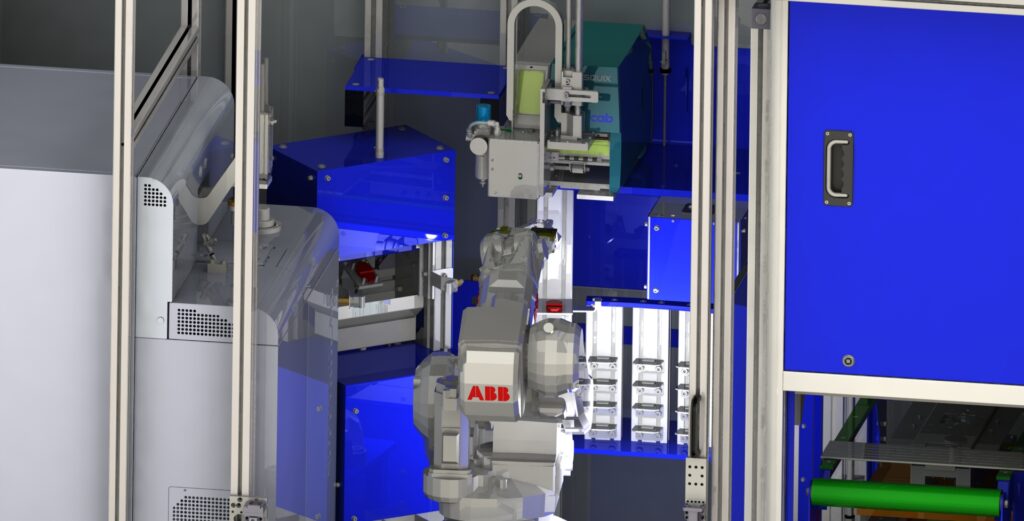

ROBOT (ABB OR KAWASAKI)

QCS SAMPLE MILLING MACHINE PF100

QCS LABEL PRINTER LD100

SAMPLE CAMERA SYSTEM

RECEIVING STATION WITH AN UNPACKING FUNCTION

OES ANALZER

The QCS INDIVIDUAL CENTRAL LABORATORY can be individually designed and programmed for each of our industrial application (STEEL, CEMENT, MINING, NON-FERROUS, CHEMICAL, RECYCLING). Unlike the QCS CONTAINER LABORATORY CL100 the central laboratory covers more area, which allows to integrate several milling machines with different parameters and different analysis methods (e.g. OES, XRF/XRD, CNS or LIBS). In addition, it offers the advantage of centralization (e.g., only one software license is needed). On the other hand, the cycle to the analysis result takes longer than in a container, since it cannot be installed directly at the production site (e.g., at the melt pot). The following example is a fully automated central laboratory including sampling, sample transport, sample preparation and sample analysis of steel or nonferrous metals. Sample feeding, robot control and status monitoring are carried out via a higher-level computer-controlled control system. The cycle time depends on the scope of sample preparation.

HARDWARE:

SOFTWARE:

Our PMI-OES ROBOTIC takes over the analysis of elements for finished steel, iron and non-metal bars or tubes. Unlike the conventional process, which is carried out manually by personnel, our exchange tester provides reliable measurement results 24/7 in multi-shift operation, due to dimensionally accurate and targeted programming as well as positioning of servo motors. The measurement result including preparation for a measurement is available within 22 seconds. In case of significant deviations, the cycle is repeated up to 3 times (depending on the customer’s requirements). The system is designed in such a way that it is possible to perform up to 5 measurements in one run and to compare them with the previously calibrated target values. In addition, it is possible to perform quality control directly during production. It is possible to test either on the rounded side of the bar (from above) or on the flat face side (from the side).

ROBOT (ABB OR KAWASAKI)

QCS SAMPLE MILLING MACHINE PF100

QCS LABEL PRINTER LD100

QCS SAFETY FENCE

QCS SAFETY FENCE

QCS SAFETY FENCE

STATIONARY OES-ANALYZER

If you would like to discuss a specific topic, just request a meeting and we would love to talk about it.