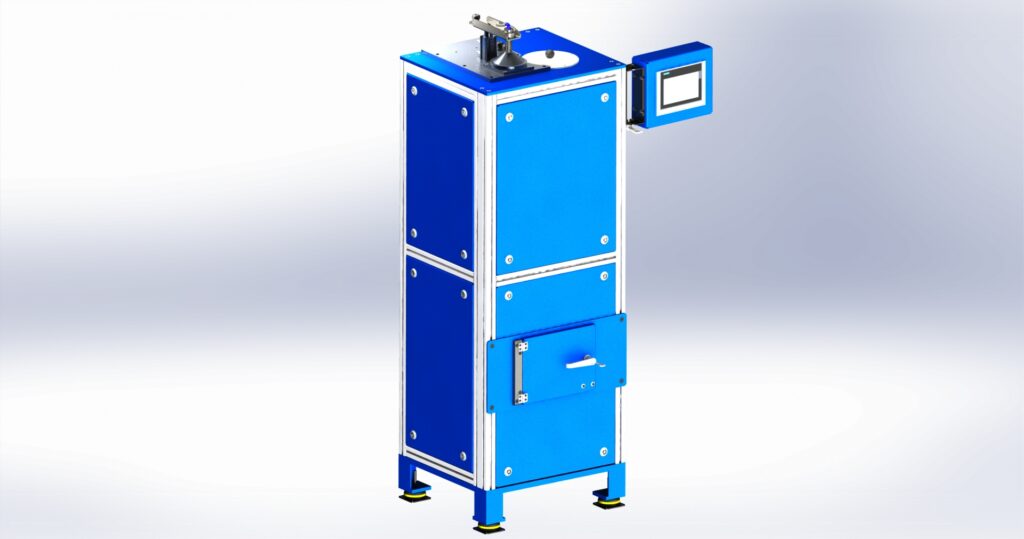

SAMPLI CUPMILL100-R: SEMI-AUTOMATED GRINDING FOR CEMENT SAMPLES

Intended use: The automatic mill is designed for fine grinding

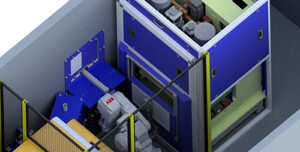

The automatic tablet press is intended for the production of sample material tablets from cement, ore, slags, soil samples, raw meal, clinker, etc. The automatic tablet press can be operated by means of the control system in a (fully) automatic, semi-automatic, or manually operated mode. The automatic tablet press is used exclusively for manual or automatic feeding of a suitable sample material into the open feed hopper. Manual or automatic starting of the plant process with the help of the control panel. Automatic closing of the feed hopper by means of a movable lid. Dosing of the required amount of sample material by the dosing unit. Uniform filling of the steel ring with sample material by the filling unit with the vibrator and beater switched on. Pressing of the sample material in the steel ring between the lower die, which is pressurized with hydraulic pressure, and the upper die. Transfer of the pressed specimen material in the steel ring onto the conveyor belt and discharge of the steel ring. Placing a cleaned empty steel ring under the filling unit. Brushing, blowing off and suctioning of all assemblies that have come into contact with sample material by the brush systems, blow-off units and the central suction unit. Placing a tested tablet in the steel ring on the ring tray and transporting it into the plant by means of the conveyor belt. Ejection of the tablet from the steel ring and cleaning of the steel ring in the ring cleaning unit.

– The use of the steel rings supplied

– The use of permissible sample materials

– The required renewal of wearing parts in the automatic tablet press

– Compliance with the inspection and maintenance work and intervals

– Observance of all instructions and information in this operating manual as well as in the third-party documentation supplied for the individual components.

Year of manufacture – 2018

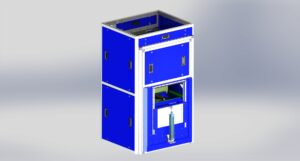

Dimensions – width = approx. 850 mm, depth = approx. 1,000 mm, height = approx. 1,560 mm

Weight – approx. 850 kg

Floor load per foot – 220 kg

Operating voltage – 3 x 400 V AC ±10%.

Control voltage – 24 V DC

Valve voltage – 24 V DC

Mains frequency – 50 Hz

Protection class – IP 54

Programmable logic controller – Siemens TP / Lauer

Power consumption – 2,0 kW 400 V 50 Hz ±10% 460 V 60 Hz ±10%

Operating pressure ( compressed air ) – 6 – 8 bar (quality 1.4.1. according to ISO 8573-1)

Compressed air consumption – 1.1 standard m³/cycle

Suction connection – D = 80 mm

Vacuum level – 160 mbar

Suction volume – 150 m³/h

Connected power – 3,0 KW

Noise emission – 76 dB (A)

Optional modified housing noise protection

Hydraulic:

You are welcome to leave your details and we will get in touch with you.

Intended use: The automatic mill is designed for fine grinding

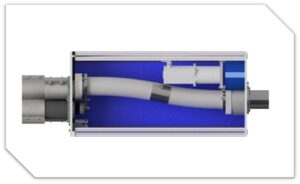

The station is used to send pneumatic tube containers to

You are welcome to leave your details and we will

You are welcome to leave your details and we will

You are welcome to leave your details and we will

You are welcome to leave your details and we will

You are welcome to leave your details and we will

If you would like to discuss a specific topic, just request a meeting and we would love to talk about it.