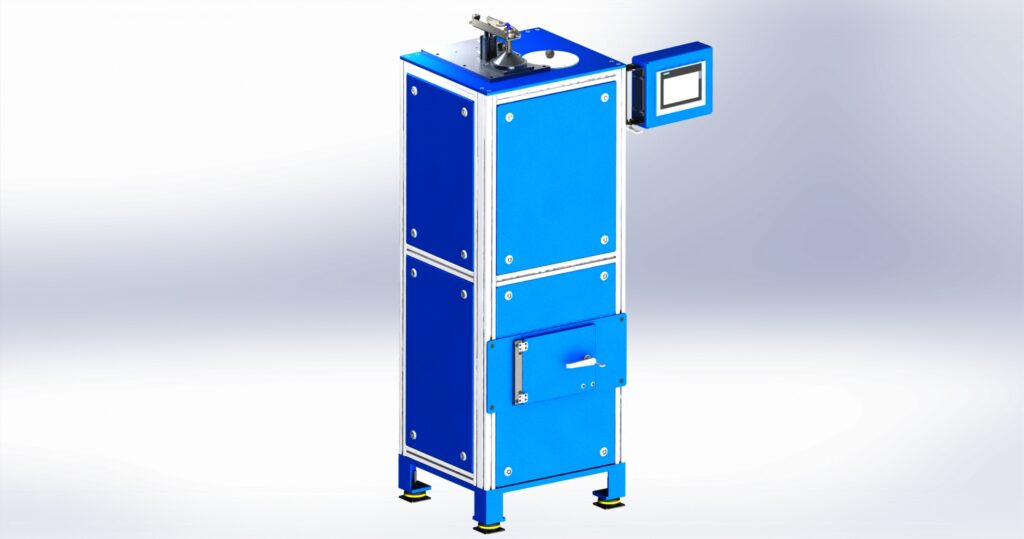

SAMPLI CUPMILL100-R: SEMI-AUTOMATED GRINDING FOR CEMENT SAMPLES

Intended use:

The automatic mill is designed for fine grinding of cement, ore, slags, soil samples, raw meal, clinker, etc. The automatic mill can be operated by means of the control system in a (fully) automatic, semi-automatic, or manual mode.

The automatic mill is used exclusively for manual or automatic feeding of suitable sample material into the feed hopper.

Manual or automatic starting of the plant process with the help of the control panel.

Automatic closing of the feed hopper by means of a movable lid.

Dosing of the required amount of sample material by the dosing unit.

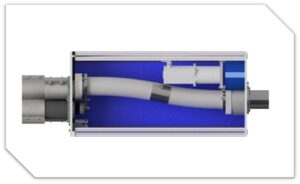

Forwarding of the sample material via the mill inlet into the grinding unit.

Dosing and forwarding of the grinding aid tablets through the tablet feeder into the grinding unit.

Grinding of the introduced sample material by rotating the eccentric grinder in a flushing grinder to flush the grinder contaminated with other sample materials through the new sample material.

One or two main grindings to obtain the desired finely ground sample material, one rinse grinding to rinse the contaminated grinding mill exclusively with grinding aid tablets for the next grinding process.

Discharge of the finely ground sample material from the grinding mill into the sample cup by the filling unit.

Removal of the filled sample cup from the filling unit and blowing off and aspirating all assemblies that have come into contact with sample material through the blow-off units and the central aspiration system.

Intended use also includes:

- The use of the grinding stones supplied

- The use of auxiliary grinding tablets is suitable for the grinding process.

- The use of permissible sample materials

- The necessary renewal of wearing parts in the automatic mill

- The observance of the inspection and maintenance work and intervals

- Observance of all instructions and information in this operating manual as well as in the third-party documentation supplied for the individual components.

Technical data of the automatic mill AM 100

Year of manufacture – 2018

Dimensions:

Width = approx. 850 mm

Depth = approx. 1.150 mm

Height = approx. 1,750 mm (without cooling car.)

Height = approx. 2,070 mm (with a cooling car.)

Weight:

– 520 kg (without cooling unit)

– 562 kg (with the cooling unit)

Floor load per foot:

– 130 kg (without cooling automat.)

– 140,5 kg (with cooling automat)

Operating Voltage – 3 x 400 V AC ±10%

Control voltage – 24 V DC

Valve voltage – 24 V DC

Mains frequency – 50 Hz

Protection class – IP 54

Programmable logic controller – Siemens TP / Lauer

Power consumption:

– 2,0 kW

– 400 V 50 Hz ±10%

– 460 V 60 Hz ±10%

Operating pressure (compressed air) – 6 – 8 bar (quality 1.4.1. according to ISO 8573-1)

Compressed air consumption – 1.1 standard m³/cycle

Suction connection – D = 80 mm

Vacuum level – 160 mbar

Suction volume – 150 m³/h

Input grain size – max. 6 mm

Noise emission – 78 dB (A) Optional modified housing noise protection

Cooling unit – Etscheid IK-V 07

You are welcome to leave your details and we will get in touch with you.

Favorite Products

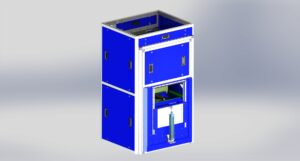

SAMPLI PELLETPRESS40-R: SEMI-AUTOMATED PRESS FOR CEMENT SAMPLES

Intended use The automatic tablet press is intended for the

SAMPLI-SRM-M: MANUAL SENDING STATION FOR METAL SAMPLE TRANSPORT

The station is used to send pneumatic tube containers to

SAMPLI SCREW-SMP: SCREW SAMPLER FOR CEMENT SAMPLES

You are welcome to leave your details and we will

SAMPLI DIVERTER-TT: DIVERTER FOR SAMPLE TRANSPORT

You are welcome to leave your details and we will

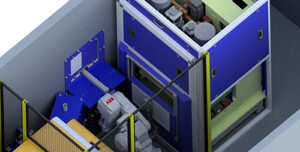

SAMPLI CONTAINER-LAB: AUTOMATED METAL ANALYSIS

You are welcome to leave your details and we will

SAMPLI MILL-FE-R: AUTOMATED MILLING MACHINE FOR STEEL SAMPLES

You are welcome to leave your details and we will

SAMPLI-RSM-UNPK: AUTOMATED RECEIVING STATION FOR METAL SAMPLES

You are welcome to leave your details and we will