Key Objectives of Quality Assurance in Production

The primary goals of Enhancing Production Efficiency through Quality Assurance include:

Customer Satisfaction: Delivering products that meet or exceed customer expectations, fostering loyalty and positive brand reputation.

Consistent Product Quality: Ensuring that products meet specified requirements and perform reliably.

Process Optimization: Identifying and eliminating inefficiencies to streamline production processes.

Cost Reduction: Minimizing waste and rework, leading to significant cost savings.blog.fp-lims.com+1blog.fp-lims.com+1

Regulatory Compliance: Adhering to industry standards and regulations to avoid legal repercussions.

Implementing Effective Quality Assurance Measures

To achieve these objectives, organizations should consider the following QA measures:

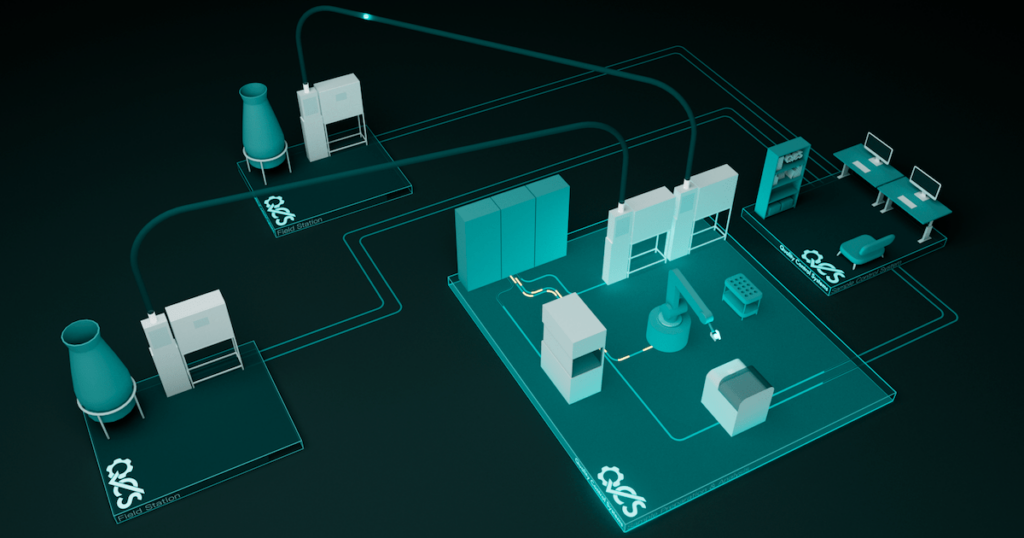

- Establishing a Quality Management System (QMS): A formalized system that documents processes, procedures, and responsibilities for achieving quality objectives.

- Regular Inspections and Testing: Conducting routine checks to detect defects early and ensure compliance with quality standards.

- Employee Training: Providing ongoing education to staff about quality standards and best practices.

- Supplier Quality Control: Ensuring that raw materials and components from suppliers meet required quality specifications.

- Continuous Improvement: Implementing feedback loops to identify areas for improvement and applying corrective actions promptly.

Role of Laboratory Information Management Systems (LIMS) in Quality Assurance

Integrating LIMS software into QA processes can be instrumental in managing data effectively, ensuring traceability, and facilitating compliance with quality standards.