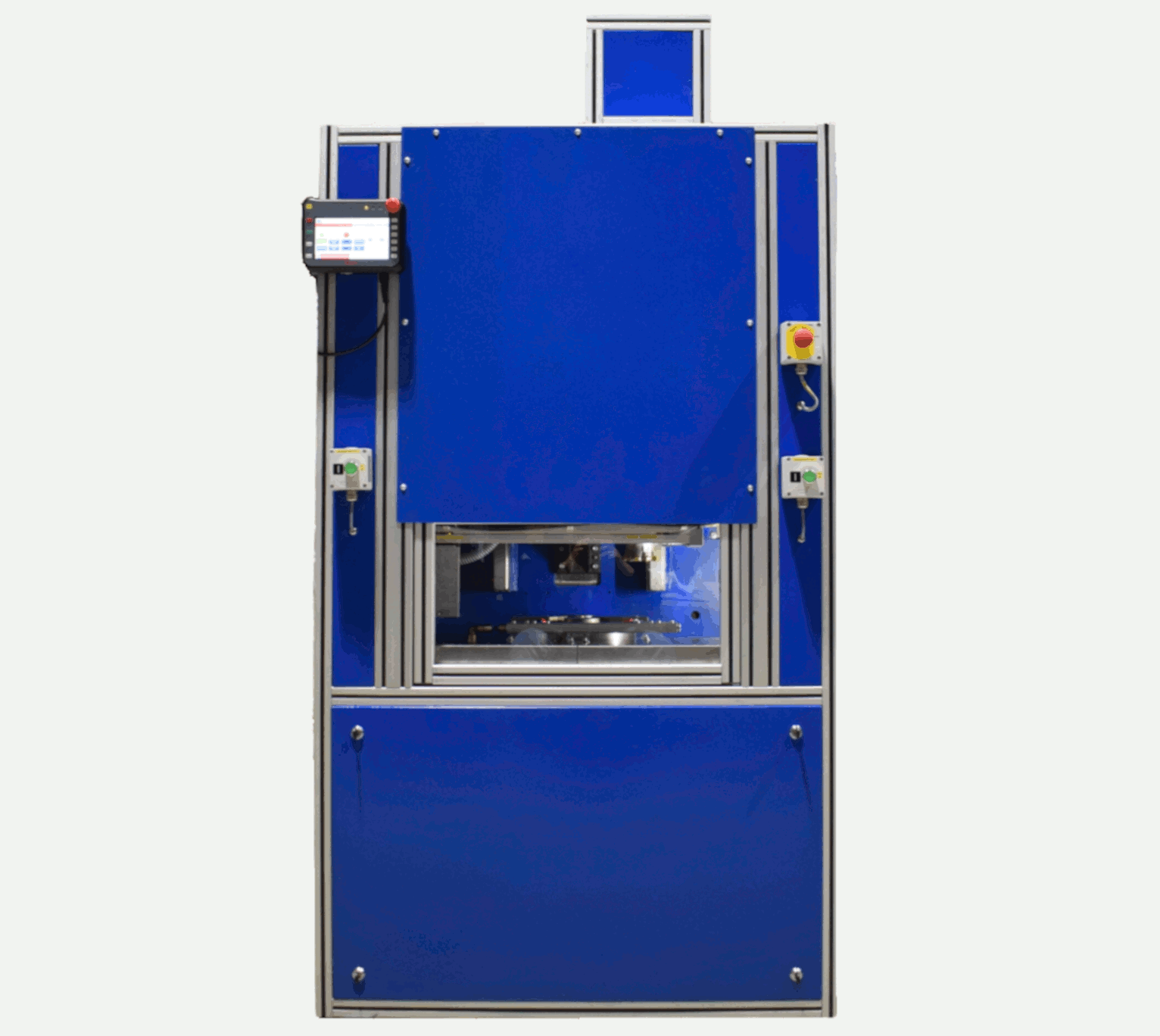

Sampli Mill-Fe-R

The Sampli Mill-Fe-R integrates automated milling technology with high flexibility, meeting the demands of modern QC laboratories. Designed for precision and efficiency, it offers optimized workflows for sample preparation.

- Compatible with both manual and automatic operations.

- Reduces preparation time with high-precision milling (0.01 mm steps).

- Minimizes vibrations through mineral composite casting.

- Ideal for pig-iron and high-hardness samples (up to 64 HRC).

Category Milling

Tags full-automated, semi-automated

Technical Data (Product Description):

- Dimensions (W x D x H): 1110 mm x 1350 mm x 2190 mm

- Weight: Approx. 1700 kg

- Voltage: 3x 400 V, 50 Hz

- Compressed Air Supply: 6 – 8 bar

- Clamping Device: 2-4 parallel clamping jaws

- Sample Materials: Steel, iron, non-ferrous metals

- Sample Shapes: Round, oval, double-thickness, square

- Max. Sample Hardness: 64 HRC

- Cutting Depth: 0.8 mm per step (0.01 mm increments)

- Cycle Duration: 18 – 35 seconds

- Sample Cooling: Compressed air

- Input Method: Front or side loading (manual or automated)

- Output Method: Robotic handling with automated chip collection

- De-burring: By integrated robot system