Precise lab monitoring of OES, XRF and XRD sample analysis and preparation in labs with SAMCOS Software I MADE IN GERMANY

SAMCOS - Sample Control Software

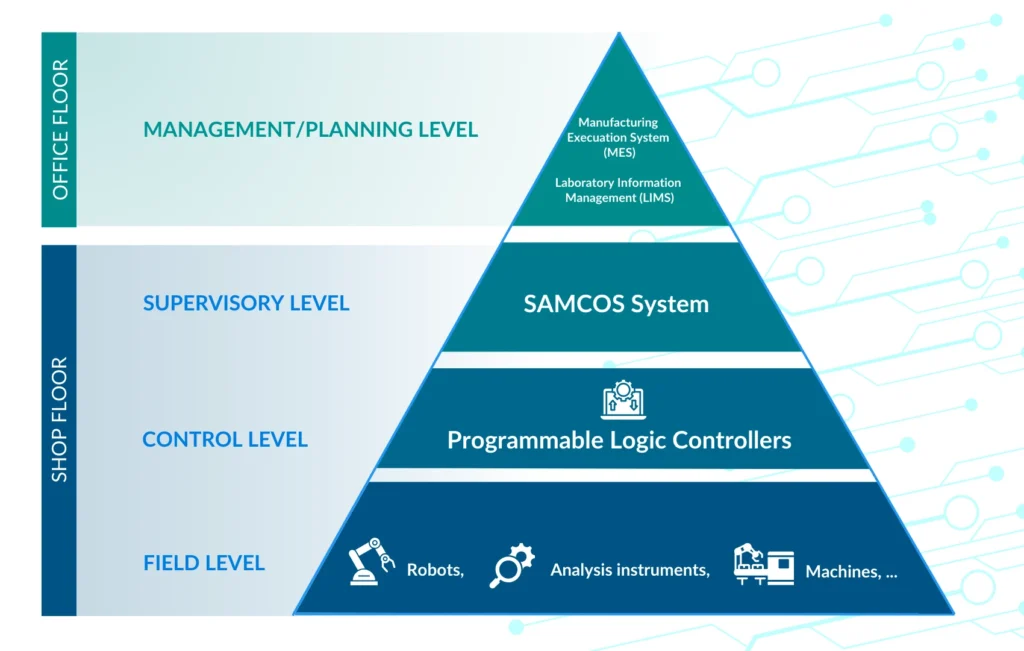

QCS can look back on almost a decade of experience in process control and optimization for the automation of OES, XRF and XRD analyses. This is why our systems achieve optimal process reliability. The workshop network displays real-time performance so that all components at field level, such as analytical instruments, machines and sensors, can communicate without delay and at reproducible transmission rates. Automation control is realized both by sophisticated PLC programs and – at a higher level – by the SAMCOS software modules. In addition, the universality and openness of the QCS solutions make it very easy to communicate with all customer office applications at management and planning level to ensure optimum lab monitoring. Typical IT systems on the office floor include ERP or LIMS applications.

Structural overview - Lab Monitoring

This minimizes unforeseen shutdowns, long downtimes, and extensive maintenance work on the system.

Control and visualization of the system:

Data reporting and analysis:

SAMCOS software systematically collects all laboratory and plant data, displays it, and forwards it to other systems as needed. Thanks to a wide range of drivers and open interfaces, third-party components can be easily integrated.

Engineering and Maintenance:

The parameterization and programming of QCS software projects are carried out with engineering modules. Additionally, the implemented automated error detection significantly reduces the time required for installation and commissioning, among other things. With the help of service routers, QCS technicians can connect to the system, in consultation with the laboratory, to perform all necessary maintenance and repair work. As with the installation of the automation system, the highest safety and security standards are observed.

Application Area of the Software

SAMCOS is a fully integrated SCADA (Supervisory Control and Data Acquisition) system used to automate the control, lab monitoring and evaluation of all laboratory and plant processes. The SAMCOS software is fully scalable, modular and easily expandable. It is designed to integrate a wide range of application-specific machines and instruments from various original equipment manufacturers. SAMCOS can be easily integrated into the customer’s IT infrastructure and offers powerful interfaces for cross-process communication. This allows SAMCOS to easily connect to other instances on the shop floor and in the office, such as Manufacturing Execution Systems (MES) or Laboratory Information Management Systems (LIMS).

Sample registration

Automated and manual registration of samples.

Samples Routing

Routing of samples by the System according to the sampling priority.

Management of Working Process:

- Overview of the sample status.

- Overview of the processing status of all the samples in the System.

- Overview of the operating status of the system.

- Setup of interfaces to all system components and office floor systems.

- Setup of interfaces to all integrated system components and office floor systems.

- Management of Recal-samples.

Comprehensive overview of all key performance indicators and improvement of process efficiency as well as the reproducibility of sample preparation and analysis:

Processing of analytical data:

Recording, display and processing of analysis results.

Validation of analytical data:

Determination of the measurement uncertainty.

Lab Monitoring of the system performance:

Summary of the sample data (Sample

Vita).

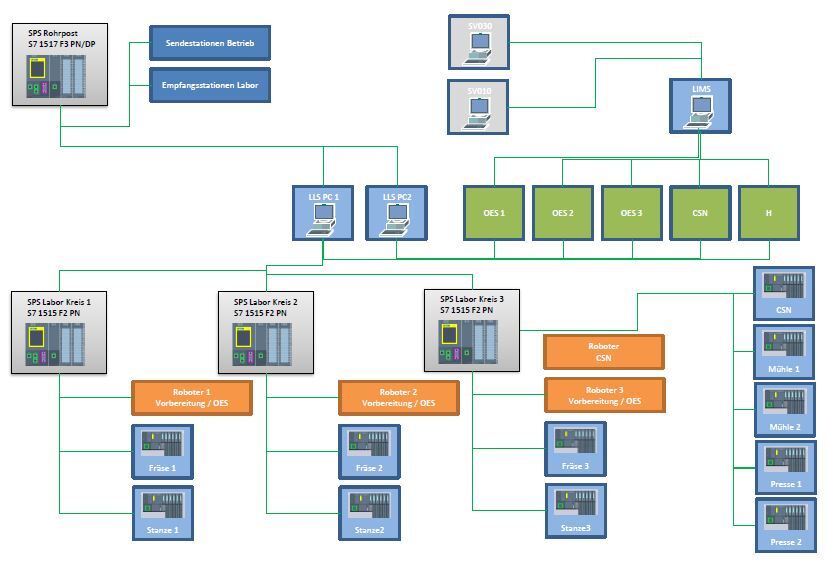

SAMCOS has integrated communication channels for Siemens programmable logic controllers (PLCs). Connections to other components are generally established using TCP/IP-based techniques, including standardized communication interfaces like XML, JSON, and OPC. Additionally, proprietary interfaces based on peer-to-peer socket applications are typically set up for analysis and handling instruments. SAMCOS comes standard with a comprehensive interface library for all leading instrument manufacturers, such as ThermoFisher, SPECTRO, Bruker, and OBLF. Besides TCP/IP networks, SAMCOS can also be used for implementing serial connections in the form of point-to-point connections and fieldbus systems.

The shop-floor network is generally based on an industrial TCP/IP standard, allowing connections via cable, fiber optic, or wireless. The network is designed for full interoperability, meaning that not only QCS machines but also all other components can be easily integrated, regardless of the manufacturer. Deterministic networks and real-time communication ensure that all time-critical and process-relevant applications can be executed with high reliability. The topology of the shop-floor network can be individually tailored to meet the requirements of each customer. If necessary, redundant ring structures can be provided for the customer’s processes to enable seamless switching. The integration of the shop-floor network into the analysis and enterprise communication of the office floor can be done in various ways.

Configuration 1

The optimal solution (configuration 1) for lab monitoring is for SAMCOS computers or servers to be integrated into both the workshop and office networks. In this case, SAMCOS receives the data from the analytical instruments integrated into the workshop network and then forwards the data to the corresponding instances on the office floor. This configuration provides a high level of cyber security as both the hardware and all workshop components are completely isolated from internet access.

SAMCOS is integrated into both the workshop network and the office floor network, receiving analysis data and forwarding it to the appropriate office floor instances. This is the preferred solution for lab monitoring.

Configuration 2

If SAMCOS is not part of the software system (Configuration 2), the analysis results are typically forwarded directly from the analysis instruments to the office-floor network. For this purpose, the spectrometers are usually directly connected to a switch within the office-floor network.

RELIABILITY AND USER-FRIENDLINESS

QCS offers an excellent overview of all pending, current, and already processed samples.

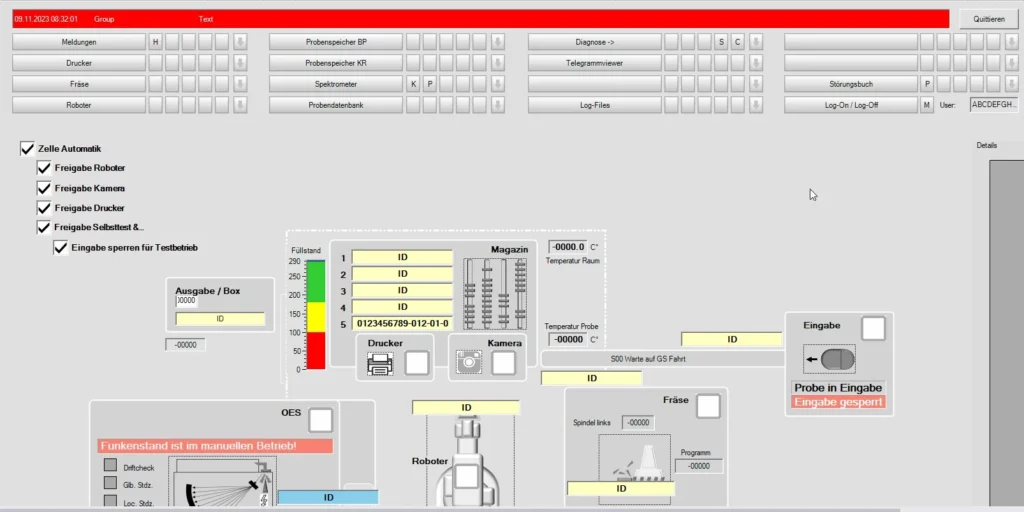

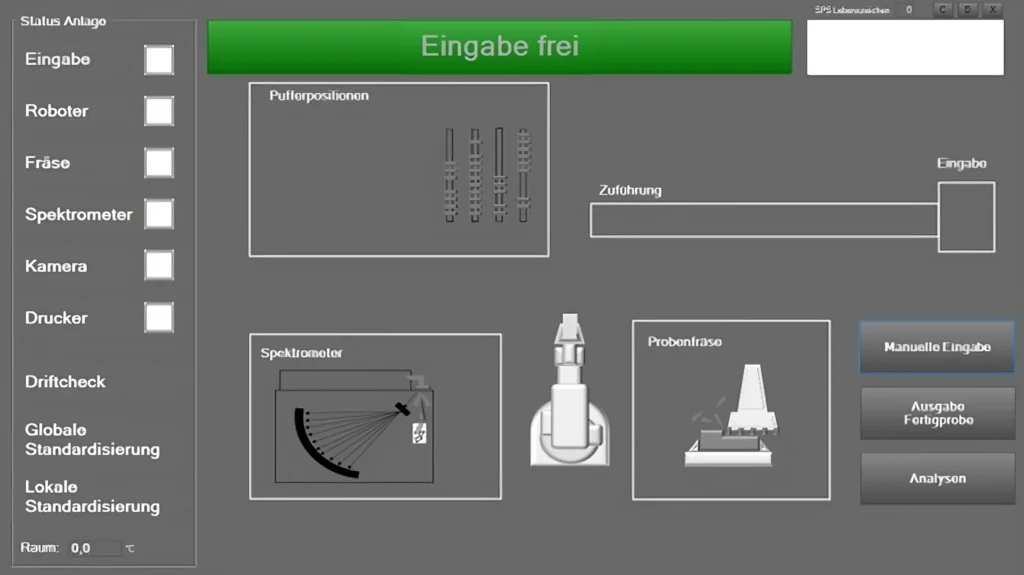

Clear graphical user interface:

- Clear representation of the functional status of the automation system.

- Clear symbols for the status of automation machines and samples.

- Easily accessible functional units.

Overview of all system components:

- Overview of all magazines in the system.

- Listing of all relevant messages, errors, and alarms.

- Overview of the maintenance status of all system components.

Access to all the relevant samples and Routing information:

- All relevant sample information is available with a click.

- Ability to centrally retrieve and modify worksheet information.

- Ability to manually trigger sample movements.

Work process configuration:

- Excellent control of sample preparation via worksheets.

- Simple and user-friendly configuration of various worksheets.

- Continuous online updating of worksheet information.

REFERENCE SAMPLE MANAGEMENT AND CONTROL

The management and control of reference samples, including lab monitoring and calibration of samples, is a significant challenge in laboratory control.

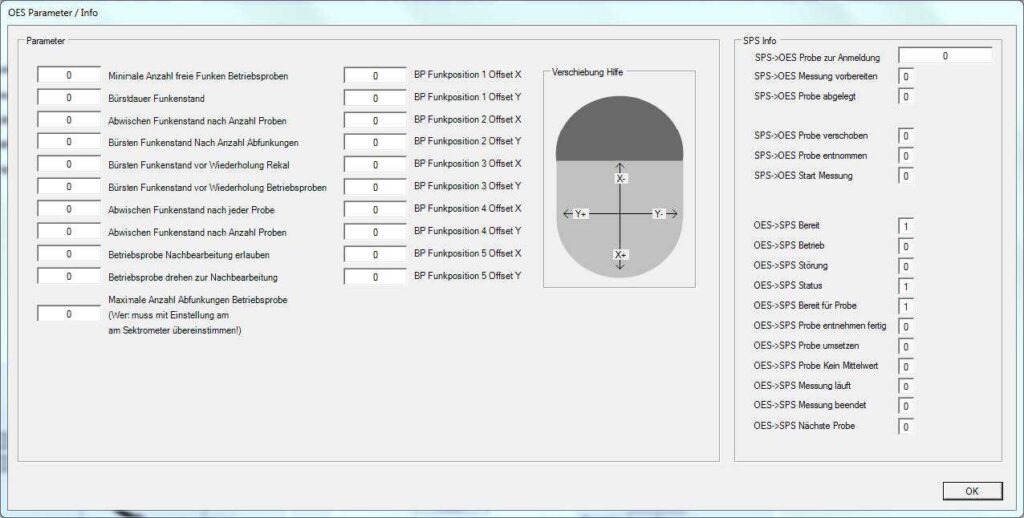

Reference example configuration:

- Intuitive configuration menu for calibration and monitoring samples.

- Easy entry of sample dimensions and spark positions for

OES analysis. - Current overview of sample condition, height, and remaining spark positions.

Configuration of Recal-sample groups:

- Grouping of Recal-samples.

- Clear menu navigation and sample display.

- Easy management of parameters for sample preparation and analysis.

Creation of Schedules for Recal Samples:

- Simple creation of schedules for measuring reference samples.

- Numerous configuration options.

- Graphical display of schedules.

Creation of Worksheets for Recal Samples:

- Easy and convenient creation and editing of worksheets.

- Numerous configuration options.

- Easily adaptable to the requirements of the respective analysis instrument.

SPARKPOINT MODULE: AN AUTOMATED VISION SYSTEM FOR OPTIMIZING SPARK POSITION

The module is specially designed for the automated inspection of sample surfaces with regard to lab monitoring using vision systems. Based on camera images and customer-specific parameters, the SparkPoint module calculates the optimum spark position for optical emission spectroscopy (OES). The SparkPoint module can be used for steel, ferrous and non-ferrous samples.

Surface with holes or ridges

Curved surface or non-perpendicular

Humid surface or too hot

Powerful Configuration Tools:

- Numerous options for configuring basic parameters and conditions.

- Easy definition of sample shape and size, spark point diameter, and number of analyses.

- Specification of the distance between spark points, to the sample edge, and to the pin.

Multi User System

Overview of the Functional Status of the Automation:

- Remote operation of SAMCOS.

- Display of unit status, position of individual samples, unit errors, robot positions, etc.

- Buttons guide the user to overview windows and other forms.

Unit Form:

- Ability to change the status of individual units (unit mode).

- Ability to send commands, including all necessary programs to the unit.

- Ability to read the unit configuration and available commands from SAMCOS.

Sample Form:

- Ability to move a sample to the desired position.

- Ability to read possible positions from SAMCOS.

- Feedback to the user on whether the command was executed or not.

Sample Registration:

- Manual registration of samples in the System.

- Entry of various sample information through input fields.

- Automated configuration of selection fields by SAMCOS.

HANDLING SYSTEM CONFIGURATION

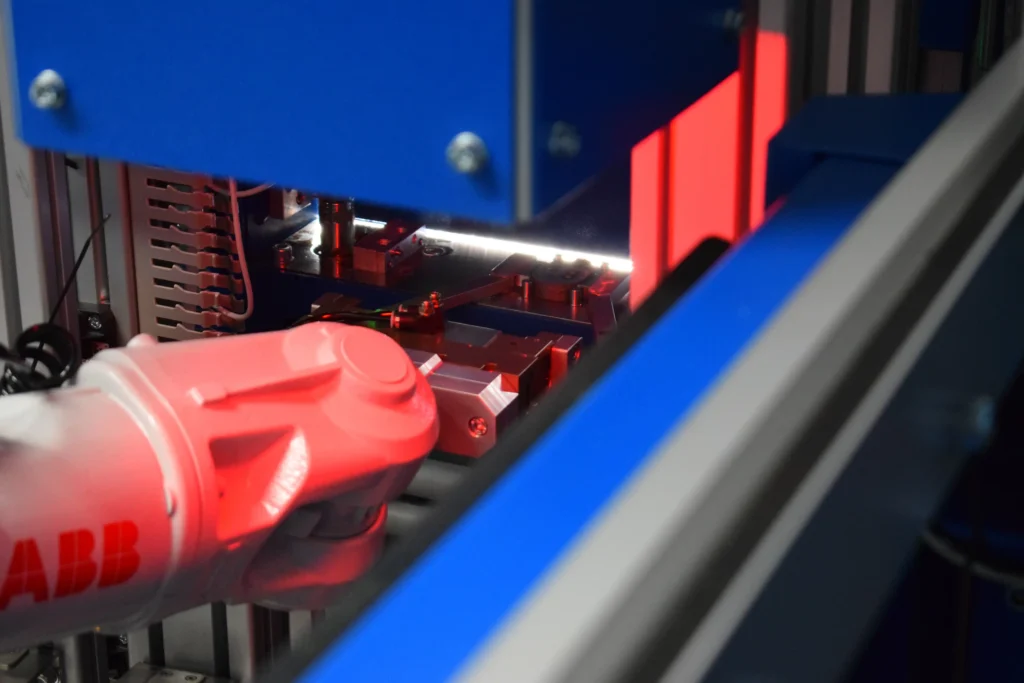

- Easy implementation of handling systems like robots.

- Simple creation, configuration, and modification of sample positions in the system.

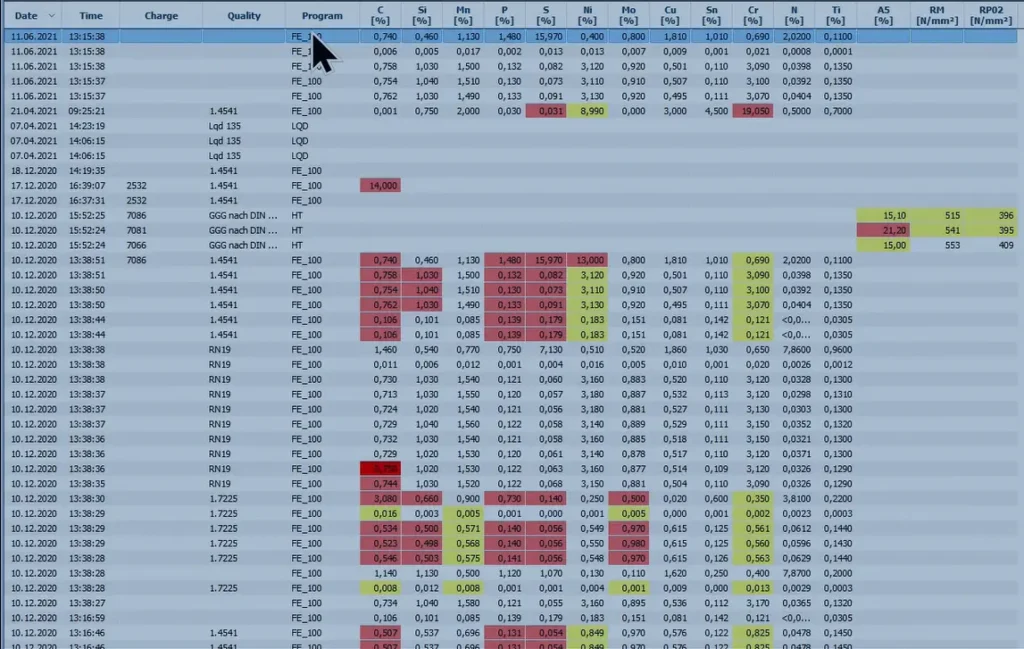

DISPLAY AND PROCESSING OF ANALYTICAL RESULTS

- SAMCOS includes preconfigured interfaces for a wide range of analytical instruments.

- Data can be displayed in tabular form on various dashboards and processed manually or automatically, with all changes automatically logged.

- All data can be tracked in various ways and used in lab monitoring.

Clear presentation of analytical data:

- Automated data collection from all integrated analytical instruments via network connections (SMB, TCP, FTP).

- Tabular display with extensive functionality (grouping, color coding, etc.).

Processing and Forwarding of Analytical Data:

- Easy data processing for users with appropriate permissions.

- Manual or automated data transfer to higher-level systems based on configurable rules.

Automated lab monitoring of analysis data:

- Lab monitoring according to defined or transferred threshold values.

- Display on easy-to-understand dashboards.

- Automated notifications of authorized users about threshold violations.

Custom Dashboards:

- Customizable configuration of dashboards.

- Quick overview of the system’s performance status.

Reduce Your Analysis Time

Reach out to us for optimizing your sample preparation!