Fastest OES, XRF, and XRD analytics through industrial pneumatic tube systems to the lab with speeds up to 40 m/s. I MADE IN GERMANY

Expertise in Industrial Pneumatic Tube Systems

Pneumatic tube systems have been used since the 1960s for the rapid transport of materials or samples and are still in use today—whether in hospitals, cash logistics, pharmacies, or in harsh industrial conditions. The technology is based on rapid transportation using air as the driving force. Our expertise focuses on the transportation and sampling of samples in metalworking plants and cement plants.

Long-standing Expertise

The experience of our team goes back to the beginnings of PFAFF’s industrial pneumatic tube post systems. This means that we have more than 40 years of experience in our ranks. Our team has already installed numerous industrial pneumatic tube systems for the transport of samples at various sampling points in steel and aluminum factories, foundries and cement plants to a central production laboratory or predefined “satellite laboratories”.

Core Components of Industrial Pneumatic Tube Systems

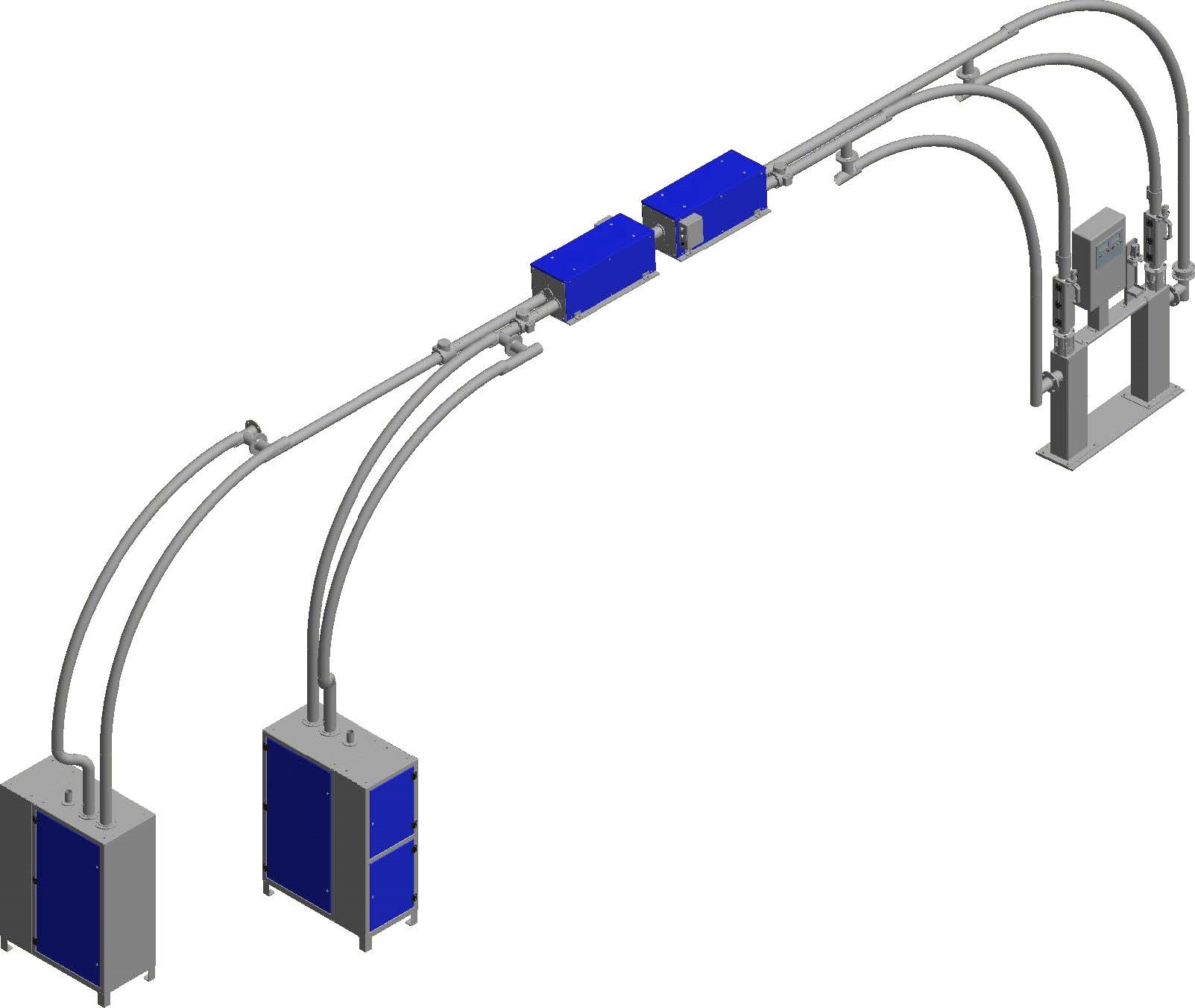

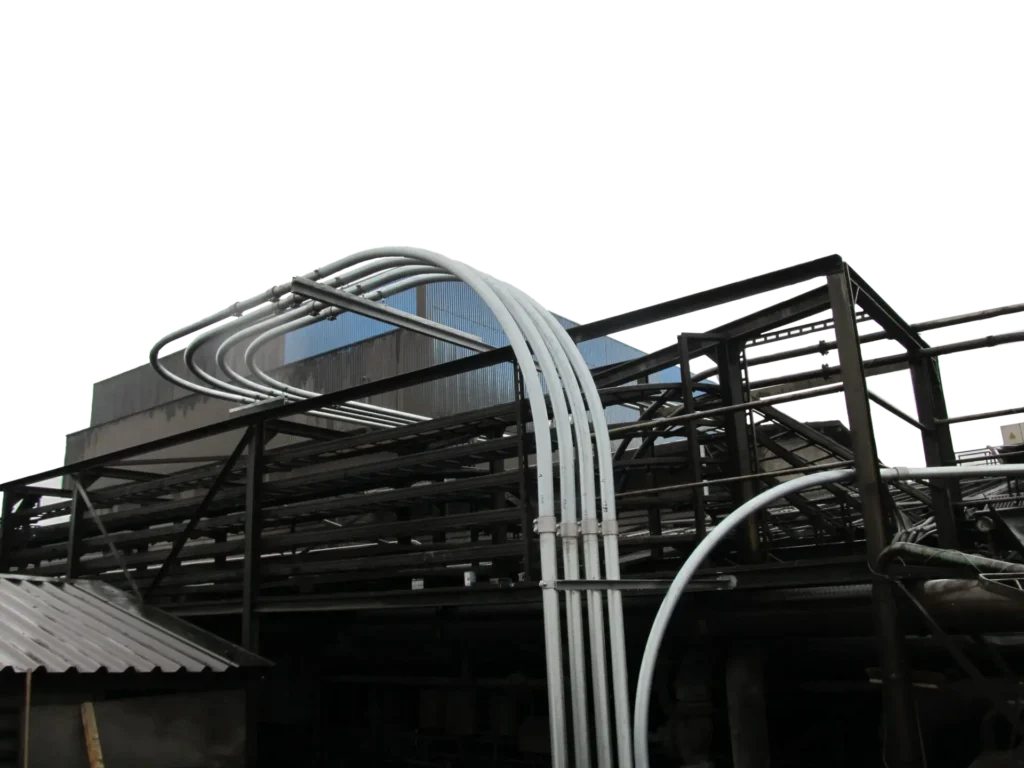

Manual, semi-automated or optionally fully-automated sending and receiving stations are available both near the production process and in the quality laboratory. One or more air blowers integrated into the industrial pneumatic pneumatic tube system generate a positive or negative pressure that transports the carriers (also known as “capsules”) at speeds between 8 and 20 m/s. The speed depends on the right choice of carrier and the pneumatic tube installation. The speed depends on the correct choice of carrier, pneumatic tube installation and blower integration. With specially configured pneumatic pipelines and special preparation of the pneumatic tubes, speeds of up to 40 m/s are sometimes possible. Pneumatic pipes with an outer diameter of 80 mm and an inner diameter of 75 mm are usually installed. Systems with other diameters are also available on customer request. A typical industrial pneumatic tube project includes:

- Sending and receiving stations directly near the production process

- Sending and receiving stations for the laboratories

- Transport pipes, pipe bends, and pipe diverters

- Transport blowers (alternatively with compressed air or

nitrogen)

- Project-specific control hardware and software

- Operator terminals for entering sample identifiers

- Monitoring sensors and software for automated sampling

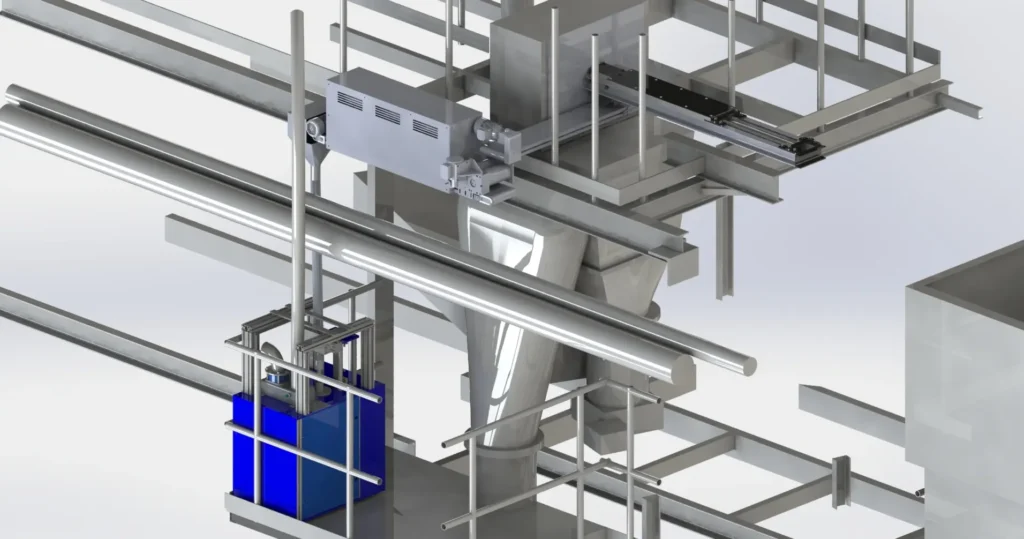

For cement sampling, various sampling systems can be integrated into the sending and receiving stations (screw samplers, air slide samplers, spoon samplers, clinker samplers, piston samplers, or others) to ensure a fully automated process.

Carrier Systems and Unpacking Stations as Means of Automation

Depending on the type of sample material, different pneumatic tube carriers are used. Different sample forms can also be handled fully automatically. Plastic carriers are used for cold powder samples and other light materials. Carriers made of aluminum are necessary for hot powder samples and steel or iron samples. For steel or metal samples (such as ‘Lollipops’ or similar), a special carrier with a clamping device and temperature-resistant material is used. The carriers for cement samples contain different volumes for dosing. This allows both process-safe sample handling in fully automated systems and extends the service life of the pneumatic tube carriers.

The sending and receiving stations, whether in the production process area or in the laboratory, can be operated manually, semi-automatically, or fully automatically. In the case of manual use, the carrier containing the sample material is manually placed into the factory’s pneumatic tube station and removed at the receiving end. In the case of full automation, an integrated receiving-unpacking station in the quality laboratory ensures that:

- Powder or granular samples are automatically unpacked and dosed into one or more sample containers to prepare them via conveyor belts or

robots for further preparation and material analysis

- Steel or metal samples are released from the clamping device, possibly cooled, and sent to the appropriate processing plant via conveyor belts or

robots

- The emptied carriers are automatically returned to operation after emptying and cleaning, from where they were sent

One-to-One Piping Connections as a Crucial Driver of Process Speed

In the steel and metal industry, the requirements for very rapid sample analysis are met by direct one-to-one piping connections, enabling parallel sample transport due to time pressures. Additionally, priorities for particularly high- quality metals to be produced can be controlled much more quickly.

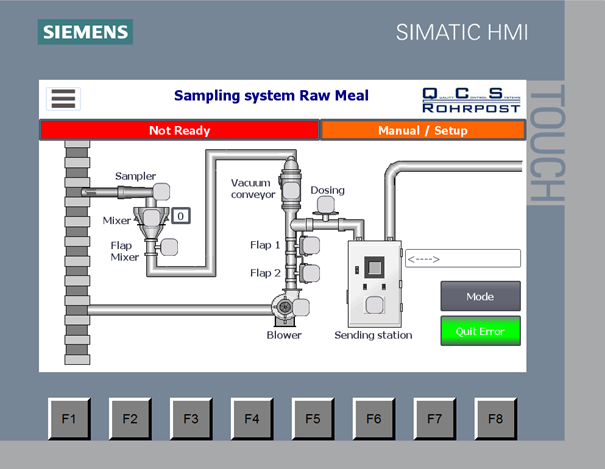

Intelligent Control and Monitoring by SAMCOS

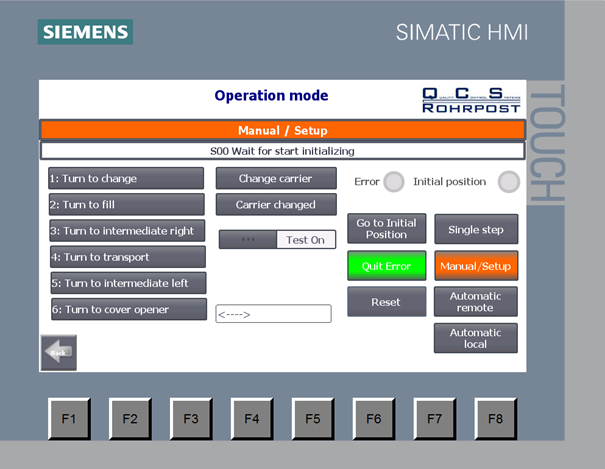

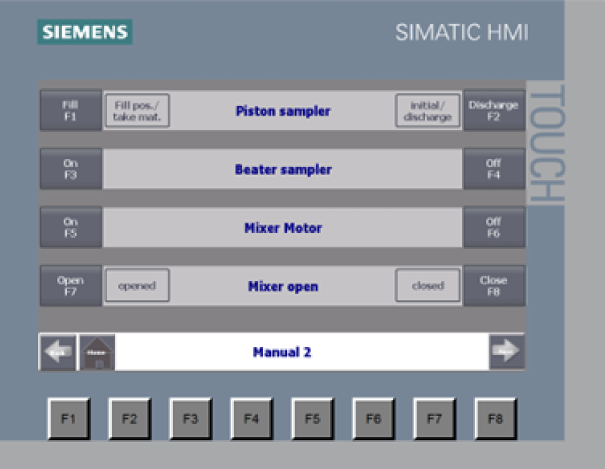

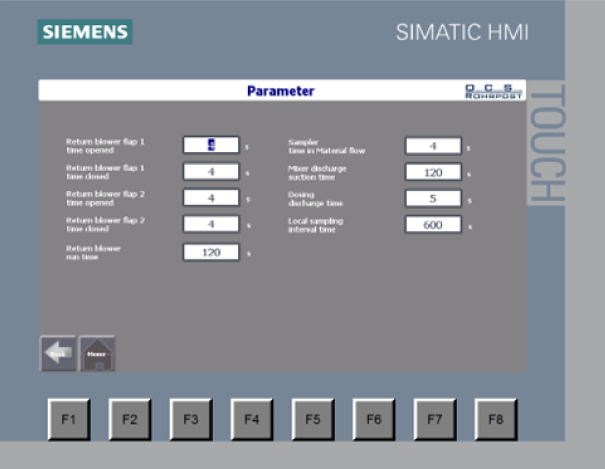

Through our intelligent system control, the most efficient and fastest sample transport and further processing in the laboratory is achieved. The control of the sampling and transport system is carried out by built-in PLC control components for device control and by our SAMCOS software, which is responsible for coordinated traffic control, sample identification, sampling variables (e.g., sample quantity), transport priorities, visualization, and other tasks. Directly via screens, faceplates (also called ‘faceplates’) provide easily accessible operational and diagnostic information about the device control. Samples are sent from the process stations to the sending and receiving stations in the laboratory in accordance with the respective sample priorities and the waiting list status. Sample details such as sampling point, product type, sampling duration, etc., are automatically forwarded to the next processing phase, regardless of whether it is a manual or automated process.

For the cement industry, SAMCOS also offers fully automated sampling processes to the laboratory. This brings numerous advantages:

Short throughput times from sampling to analysis

Efficient sampling process with minimized susceptibility to errors

High system availability (24/7 operation possible)

Easy integration with automated sample preparation systems in the laboratory

The integrated automation concept includes sophisticated priority programs. Should in the rarest case a device failure lead to reduced capacity in the automated preparation system, it is possible to reduce the automated sampling and sample transport such that samples of lower priority are bypassed or requested less frequently.